Study of a thermally conductive plastic filament for 3D printing

Finnish and Danish scientists have demonstrated 3D printing of thermally conductive plastic filaments that have potential applications as passive heat sinks for electronic devices. Their research was published in the journal Additive manufacturing .

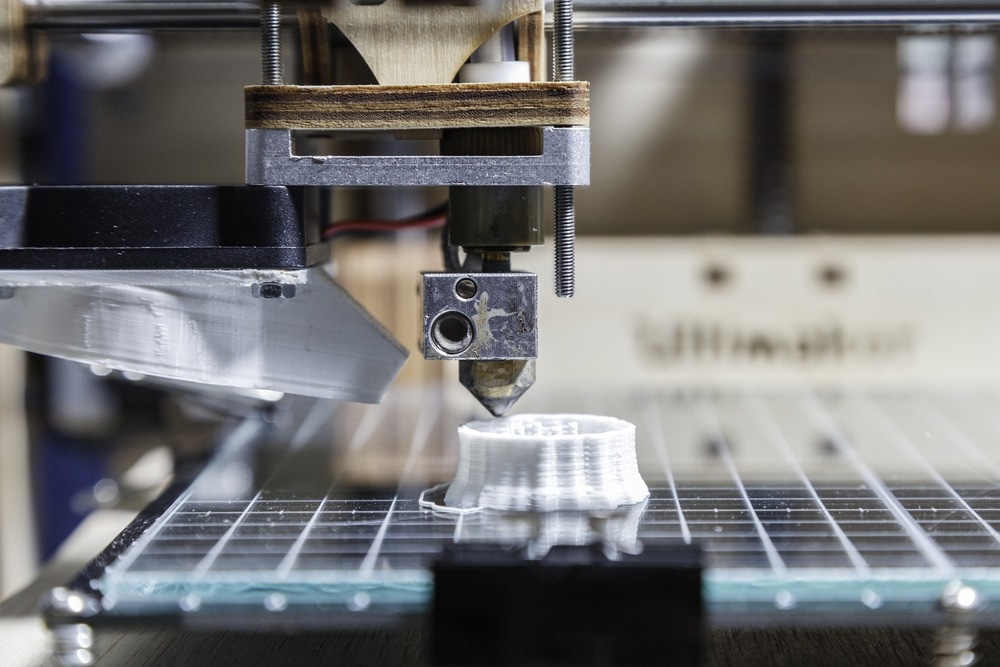

Study: Material Extrusion Additive Manufacturing and Experimental Testing of Topology-Optimized Passive Heatsinks Using Thermally Conductive Plastic Filament . Image Credit: Sergi Lopez Roig/Shutterstock.com

The need for cooling in advanced electronics

The development of innovative advanced electronics for applications such as portable devices, battery-powered devices and aerospace applications is a leading field. A key requirement of these applications is the need for efficient and reliable cooling to avoid security and performance issues.

Cooling systems require their components to possess several characteristics, such as low cost, ease of use, resistance to chemicals and corrosion, and lack of electrical conductivity. Plastics have become suitable materials for cooling systems. These materials perform better than metals, which carry the risk of short circuits and fires, requiring them to be electrically grounded.

Heat sinks transfer thermal energy from the system to another medium, usually a stream of surrounding fluid such as air or water. However, these systems can suffer from electromagnetic interference due to their shape, which is a key issue hindering their use in the telecommunications and aerospace industries.

Plastic heat sinks and additive manufacturing

The advantage of using plastic materials for heat sinks is their lack of electrical conductivity and high thermal conductivity. Recognizing this advantage, recent studies have investigated the development of polymer-based materials for use in heat sinks and cooling systems for electronic devices across multiple industries.

However, the conventional manufacture of plastics is extremely damaging to the environment. Traditional manufacturing approaches suffer from a lack of design freedom, prohibitive costs, carbon emissions and the generation of significant amounts of waste.

Additive manufacturing has several advantages over traditional methods of manufacturing materials, making it usable in a wide range of industries, from commercial products to biomedical science, aerospace, automotive, and construction. Additive manufacturing, also known as 3D printing, covers a wide range of techniques, such as material extrusion and light-assisted methods.

3D printing methods can produce functional device components with complex architectures due to their increased design freedom. By depositing materials layer by layer, 3D printing techniques produce significantly lower amounts of waste at a lower cost than conventional manufacturing methods. In addition, multi-material printing offers several possibilities for the manufacture of innovative devices and components.

Recent studies have demonstrated the suitability of additive manufacturing methods to produce elaborate plastic components with complex architectures for use in electronic cooling systems. The development of thermally conductive plastics using 3D printing methods has been extensively reviewed in recent years, providing possibilities for the future of advanced cooling systems for multiple industries.

The study

The new paper focused on the development of 3D printed thermally conductive plastic filaments for novel heatsink cooling systems. Filament topology has been explored to produce high performance passive heat sinks that exploit natural convection.

Test printing, SEM imaging, and thermal conductivity testing were used to assess filament thermal performance, a key parameter in cooling systems. Material extrusion was selected as the 3D printing technique in the study, and soluble support materials were used during manufacturing. The resulting filaments possess a complex and optimized structural design.

The heatsinks were designed with the specific filament and process in mind, and anisotropic thermal conductivity was included in the optimization process. The study demonstrated the relevance of topology optimization to improve the performance of the 3D printed passive heat sink.

search results

The optimized samples produced in the research show improved thermal performance, making them suitable for passive heat sink systems. The best designs produced using topology optimization have 10% and 20% lower thermal resistance in the vertical and horizontal directions, respectively. The designs performed better than the reference straight fin heatsinks.

Measuring the thermal conductivity values of the material under anisotropic and isotropic assumptions yielded the improved thermal performance observed in the research results. An anisotropic thermal conductivity model optimized the thermal performance of the heat sink in the vertical direction.

On the contrary, in the horizontal direction, a large distortion of the base plate was caused by the design optimization method based on the anisotropic properties. A consequent and large air gap between the heat source and the base plate occurs due to the distortion, which impairs the heat transfer in the system. This has a big impact on the potential cooling performance of the new heatsink featured in the article.

In conclusion, the study demonstrated the relevance of additive manufacturing to produce new heat sink components based on plastic filaments for advanced electronic applications. The material extrusion process can be fully controlled. However, some critical challenges need to be addressed in future research, and although satisfactory results have been obtained with the printing parameters, these can be further improved by taking thermal performance into account.

More from AZoM: The use of AI in chemical processes

Further reading

Huttunan, E et al. (2022) Material Extrusion Additive Manufacturing and Experimental Testing of Topology-Optimized Passive Heatsinks Using Thermally Conductive Plastic Filament Additive manufacturing 103123 [online, pre-proof] sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S2214860422005127?via%3Dihub